About Us

Our History

1963

Start of business

- Chemical Grouting Co., Ltd. established with a focus on improving soft grounds expected to account for a growing share of future national land development.

- Rokuro Ishikawa appointed president.

- Company promotes the widespread adoption of its advanced technology, Chemical Grouting, and research and development on related ground improvement technologies.

1967

- Company gains growing reputation for its technologies related to chemical grouting for subways, expressways, and ports; dam grouting; anchoring; and landslide prevention.

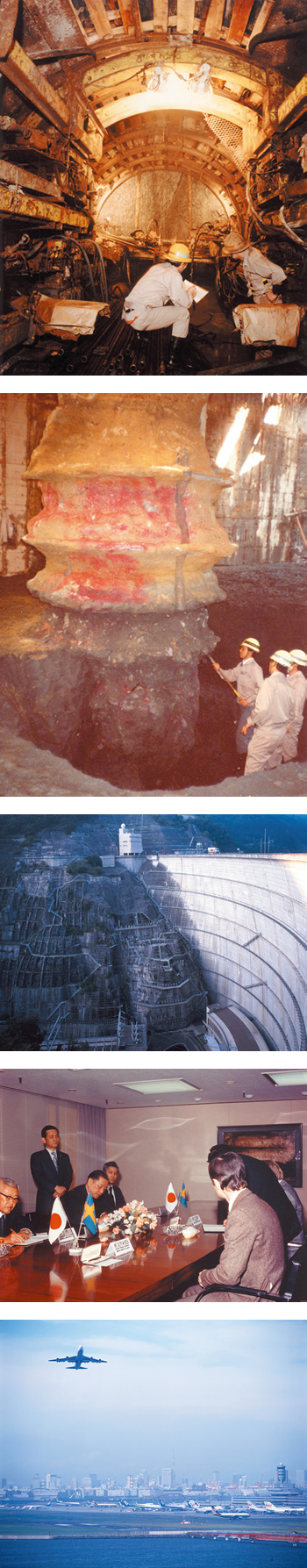

- Company undertakes water cutoff work for Seikan Tunnel, starting with survey tunnel excavation, in a project that takes 20 years to complete. Resolves various problems, including abnormal flooding, and helps establish water cutoff technologies for long, large undersea tunnels.

1971

- Develops Jet Grouting based on theory of ultra-high pressure water jets and succeeds in practical application. This is recognized the following year by an award from Japanese Society of Soil Mechanics and Foundation Engineering.

1975

- Newly developed Column Jet applied to the permanent foundations of several buildings, including Sumitomo Realty & Development’s Nakanosima building and the rebuilding of the Osaka Branch of the Bank of Japan, efforts that draw considerable attention.

1977

- Jet Grouting attracts the attention of representatives from Europe and the US at an international meeting of the Japanese Society of Soil Mechanics and Foundation Engineering.

1978

- Grants Italy-based Tecnosol a license for Jet Grouting; provides technical guidance on reinforcing the foundations of Banco di Napoli and other sites. Similar licensing arrangements concluded with Swedish, German, and other overseas companies.

1980

- Constructs diaphragm walls at depths of 100 m for the Sodegaura LNG Terminal of Tokyo Gas Company and Sodegaura Thermal Power Station of Tokyo Electric Power Company.

1983

- Achieves dominating share of ground improvement market using Column Jet to protect starting and arrival shafts and shaft bottoms for large-diameter shield.

1987

- Large-scale ground improvement projects related to waterfront development deploy across the country, including landfill runways and expressways associated with the expansion of the Haneda Airport.

1989

- Launches full-scale overseas construction in Taipei, Taiwan.

- Develops SUPERJET, an ultra-large-scale ground improvement method.

1992

- Establishes cross jet technology; develops X-JET and JACSMAN.

- Performs first construction involving ground freezing.

- Sets up SHING-HO CONSTRUCTION CO., LTD., a Taiwan-based affiliate.

- Sets up Grout Trading Co., Ltd., an affiliate for selling and exporting construction equipment and materials.

1995

- Engages in restoration of railways, expressways, bridges, and revetments following the Great Hanshin Earthquake.

- Ventures into new fields related to the environment, including contaminated soil remediation; launches first construction in Koto Ward, Tokyo.

1996

- Develops Super MC Anchor.

- Develops PneumaX, a new chemical grouting method.

1999

- JACSMAN receives first construction technology development award.

2001

- Receives award from the Tokyo Metropolitan Government for ground improvement work related to aseismic reinforcement of the foundations of monorail bridge footings in Ueno Zoological Gardens.

2002

- Executes first chemical grouting using CurveX.

2003

- Opens machine factory techno center (Tsurumi Techno Plaza) to support advanced technologies.

- SUPERJET applied in large-scale projects across the country, including underpass construction in urban areas.

- Develops Parajet.

2004

- JETCRETE developed.

2005

- Engages in disaster restoration after the Chuetsu Earthquake.

- Number of large-scale soil remediation projects increases dramatically for redevelopment and other projects.

2006

- Participates in work to improve seismic resistance margin of a nuclear power plant.

- Receives orders for aseismic reinforcement and liquefaction countermeasure projects compliant with BCP (business continuity plan) from clients across the country.

2008

- Engages in disaster restoration after the Iwate-Miyagi Nairiku Earthquake.

- JETCRETE applied in aseismic reinforcement work for the Kinuura Plant of Japan Corn Starch Co., Ltd.

- Sets up CGC Brazil.

2009

- SUPERJET applied in aseismic reinforcement of the main building of Central Government Building No.1.

2011

- Engages in disaster restoration after the Great East Japan Earthquake.

- Growing numbers of aseismic reinforcement and liquefaction countermeasure projects in the aftermath of the earthquake.

2013

- 50th anniversary of founding.

- JETCRETE applied in reconstruction at Christchurch, New Zealand, following an earthquake.

2014

- Launches soil freezing work for large-scale pilot project for construction of frozen impermeable walls for Fukushima Daiichi Nuclear Power Plant of Tokyo Electric Power Company.

2016

- Contributes in disaster restoration after the Kumamoto Earthquake.

2017

- ICECRETE applied in undersea shield tunneling for newly constructed Ishikariwan Shinko Power Plant Unit 1.